What Emissions Does a Product Generate Throughout Its Useful Life?

When a company decides to use new packaging, there is one question that should always be on the table: how much pollution do I cause from the manufacture to the recycling or disposal of my product?

This figure is what we know as the carbon footprint, and analysing it rigorously allows for more responsible, sustainable and competitive industrial decisions to be made.

What does a product’s carbon footprint really include?

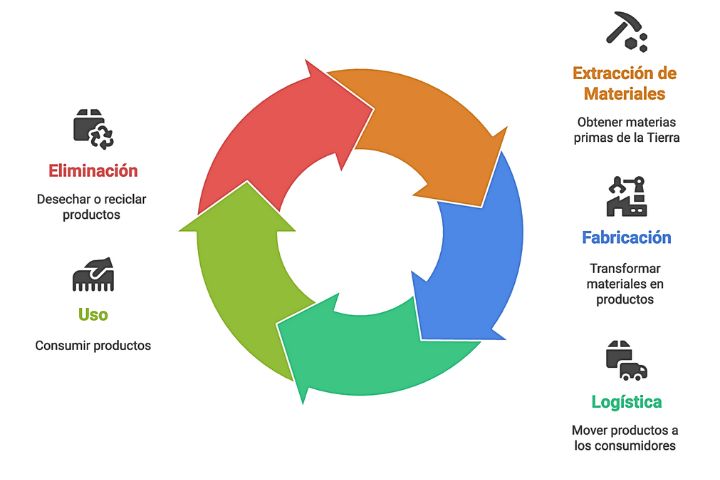

It is not just about the CO₂ emitted during manufacturing. The carbon footprint includes the entire product life cycle: from the extraction of raw materials, transport and use, to end-of-life treatment.

In sectors such as chemicals, agri-food, and pharmaceuticals, where packaging must comply with strict regulations and technical conditions, knowing this information allows sustainability to be integrated without compromising safety.

These are the main stages that contribute to the carbon footprint:

- Extraction and processing of materials.

- Manufacturing and transformation.

- Logistics and transport.

- Use phase.

- Disposal, recycling or recovery.

Why should we care?

Because it is a key indicator of a product’s real impact. Because our customers and partners increasingly value it. And because it also helps to comply with environmental regulations, improve ESG scores and stand out in tenders or audits.

Furthermore, having accurate data on your carbon footprint makes it easier to obtain environmental certifications such as ISO 14067 or PAS 2050, and allows you to develop continuous improvement strategies with measurable objectives.

Where emissions are most concentrated

Each product has its own profile, but in industrial packaging, some phases tend to stand out for their high environmental impact.

One of these is the extraction of raw materials. Materials such as virgin plastic or stainless steel have a much higher CO₂ footprint than alternatives such as recycled kraft fibre or certified cardboard.

Other critical phases in terms of emissions are:

- The energy used in the manufacturing process.

- The weight and volume of the packaging during transport.

- The possibility of reusing the product.

- The ease with which it can be recycled without generating complex waste.

How can we reduce that footprint in the packaging sector

From design to logistics, some decisions make a big difference.

Choosing lighter, stackable packaging, for example, reduces logistics emissions on each journey. Opting for recyclable materials or those from renewable sources also reduces the impact from the outset.

And if, in addition, the product can be reused, the production of new packaging is avoided, extending its useful life.

In our processes, we have implemented measures such as:

- Use of recycled fibres and certified materials.

- Energy optimisation in our production plant.

- Durable closure systems that allow reuse.

- Elimination of mixed components that hinder recycling.

How is carbon footprint calculated?

There are specific methodologies for this, such as ISO 14067 or the Greenhouse Gas (GHG) Protocol. These tools enable life cycle analyses to be carried out that measure the CO₂ equivalent emitted at each stage.

In the case of packaging, the analysis can range from the origin of the cellulose or polymer to emissions from transport on pallets, the possibility of reuse or the need for special treatment at the end of its use.

For many companies, this calculation is not straightforward, which is why we offer technical advice that enables them to choose packaging with a lower environmental impact and justify their decision with documentation for audits or certifications.

Ask at the outset: the gesture that changes the outcome

Often, the key lies in asking the right questions before choosing a container. A decision made without considering the environmental impact can lead to more emissions, more waste and higher costs in the long term.

Some key questions we recommend asking yourself are:

- What is the origin of the materials?

- What will be its weight and volume during transport?

- Can it be easily reused in industrial conditions?

- What are its actual recycling possibilities?

These questions not only help to comply with legal or social responsibility requirements. They also enable the identification of opportunities for savings and operational improvements.

Choosing a container means choosing a way of producing

Every packaging decision has consequences. Not only in terms of logistics or regulations, but also in how the company positions itself in relation to climate change, responsible innovation and the efficient use of resources.

That is why we believe that the first step in reducing emissions is to ask questions. Understand the impact. Demand data. And make informed decisions that improve not only the final product, but the entire process surrounding it.

Are you looking for approved, safe packaging with a low carbon footprint? We can help you find the best option for your product, your sector and your objectives.

You may also be interested in: