History of Kraft Carton Packaging

Kraft cartons, including Kraft drums, represent a revolution in the packaging world, offering a robust, versatile and, above all, sustainable solution. This material, with its distinctive brown colour and remarkable strength, has become a symbol of environmental responsibility in the packaging industry.

Origins of Kraft board

The origins of Kraft paperboard go back to the end of the 19th century (1884), when Carl F. Dahl, a German chemist, developed a new paper production process that proved to be much stronger and more durable than the methods that had existed up to that time.

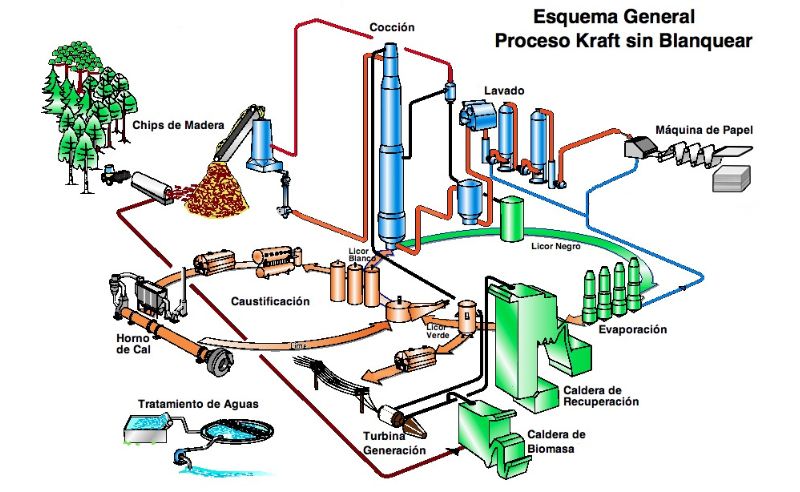

This process, known as the Kraft process (from the German word “kraft”, meaning “strength”), involved the use of sodium sulphate in the wood pulp cooking process, which produced a paper of great strength and durability.

The Kraft process revolutionised the paper and packaging industry for several reasons. Firstly, it allowed the use of different types of wood, including those with high resin content, which were previously considered unsuitable for paper production.

In addition, the Kraft process produced a paper that was stronger and able to withstand wet conditions, making it ideal for a wide range of products.

Over time, this strong paper began to be used not only in sheet or roll form, but was also adapted to create paperboard, by laminating several layers of Kraft paper. This led to the development of Kraft paperboard, which inherited the strength and durability properties of the original Kraft paper.

Kraft paperboard quickly became an ideal material for the manufacture of boxes and other types of packaging, due to its strength, its ability to protect products during transportation and its sustainability.

Its popularity has continued to grow over the years, adapting to the needs of different industries and responding to the growing demand for environmentally friendly packaging solutions.

Kraft paperboard in the 20th century

Over the course of the 20th century, Kraft paperboard established itself as a mainstay of the packaging industry, responding to the growing demands of a rapidly industrialising and globalising world.

Its strength, flexibility and low cost, coupled with advancing production technologies, facilitated its adoption in a wide range of industries from food to electronics.

The 20th century ushered in an environmental consciousness that valued the green credentials of Kraft paperboard, such as its biodegradability and recyclability, positioning it as a more sustainable alternative to less eco-friendly packaging materials.

Thus, Kraft paperboard not only transformed logistics and product marketing globally, but was also ahead of its time in terms of sustainability.

Success stories and innovative uses

Kraft cartons have been the subject of numerous success stories and innovations that have revolutionised the way brands interact with their consumers, demonstrating their versatility and sustainability.

Food and beverages

Companies in the food and beverage industry have adopted Kraft paperboard to create attractive and environmentally friendly packaging.

A case in point is that of coffee shops using recycled Kraft paperboard cups, offering a sustainable alternative to plastic cups.

In addition, several organic food brands have opted for Kraft cardboard packaging to underline their commitment to the environment, using vegetable inks and minimalist designs that highlight the naturalness of their products.

E-commerce

The rise of e-commerce has driven demand for innovative and sustainable packaging solutions. Kraft board has been the answer for many companies looking to reduce their carbon footprint.

One example is the use of customised Kraft cartons, designed to protect products during shipment without the need for additional filler materials, thanks to the incorporation of inserts and partitions tailored to each product.

Cosmetics and personal care

The cosmetics and personal care sector has seen Kraft carton board as an excellent opportunity to reinforce its brand image with an ecological touch.

Natural and organic cosmetics brands have innovated with Kraft cartons that are not only recyclable and biodegradable, but also offer an elegant and distinctive presentation, appealing to the environmentally conscious consumer.

Technology and electronics

Even in the technology and electronics industry, where product protection is critical, Kraft paperboard has found its place. Technology companies have begun to package their products in reinforced Kraft paperboard, demonstrating that it is possible to combine high protection with environmental responsibility.

These packages often incorporate ingenious designs that eliminate the need for plastics and foams, taking advantage of the inherent strength of Kraft paperboard.

Art and education

Kraft board has also inspired creativity in the field of art and education, where it has been used to create everything from teaching materials and educational games to packaging art. Its surface lends itself to being drawn, painted or printed on, allowing customisations that turn packaging into an interactive and educational experience.

Kraft cartons don’t just tell the story of a material that has stood the test of time; they tell the story of the evolution to a greener future. Its legacy and potential continue to inspire companies and consumers to make packaging choices that respect and protect our planet.

The story of Kraft paperboard is a reminder that innovation and sustainability can go hand in hand, leading the way to a responsible and conscious packaging industry.

FAQs

How is Kraft paperboard recycled and managed at the end of its life?

Kraft paperboard is recycled through a collection and separation process, where any non-paper material is removed, shredded and mixed with water to create a pulp. This pulp is cleaned, decontaminated and processed into new paper and board products, closing the life cycle of the material in an environmentally friendly way.

Is it more expensive to use kraft packaging compared to other materials?

The cost of kraft packaging can vary depending on a number of factors, such as purchase volume, design specifications and additional treatments. Although they can be more expensive than some plastic materials, their positive environmental impact and effectiveness in protecting products often justifies the investment. In addition, their aesthetic and ecological appeal can increase the perceived value of products.

How is Kraft packaging customised?

Kraft cartons can be easily customised using printing techniques such as screen printing, digital printing and embossing. This allows brands to include logos, specific designs and environmental messages, enhancing product presentation and reinforcing brand identity.

You may also be interested in: