Kraft Drum Manufacturing Process: From Paper to The Final Drum

In the world of industrial packaging, Kraft drums stand out for their strength, versatility and sustainability. These containers are essential for the safe transport and storage of a wide range of products, from food to chemicals.

Below, we will explain the process of how paper is transformed into a robust and reliable drum.

Beginning of the process: the creation of the tube

It all starts with the manufacturing of the tube, the body of the drum. The paper rolls purchased are of different lengths to avoid losing any millimetres. These are cut to the exact size of the shaped drum so as not to lose any material.

Forming the tube

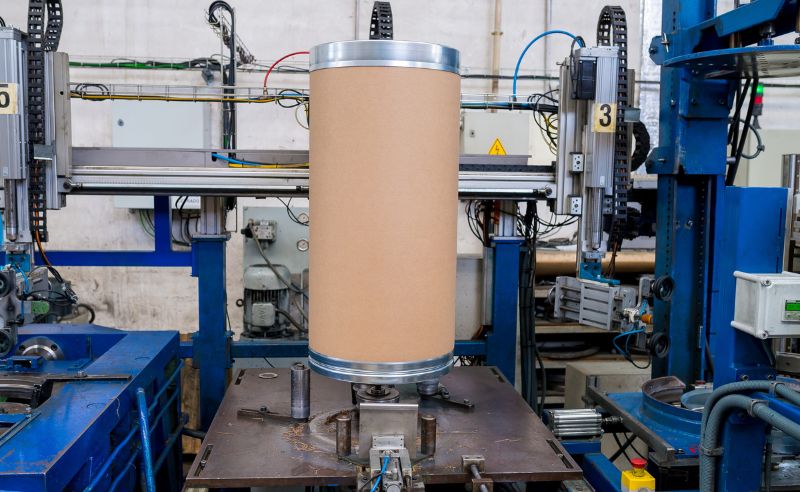

This tube is formed by winding layers of Kraft paper around a mandrel, creating a strong cylindrical structure. The quality of the paper and the precision of the winding are critical to ensure the strength of the final drum.

The reel is placed in the machine that will form the tube. The cardboard is passed through fibre breakers so that it can be handled well.

Pipe cutting

It is glued and reaches the end where the tube is glued. This tube will later be cut to the measurements we are interested in.

Tube machining

Once the tube is ready and laid out on the production line, one of the most critical phases begins: the addition of rings. At this point, the different stages are machined to place two rings, one upper and one lower, around the tube.

This process, known as beading, involves deforming the metal of the hoops so that they fit snugly and securely to the body of the drum, providing a secure and sealed structure. The rings not only reinforce the tube but also give the container consistency.

Bottom

Once the rings have been fixed to the body of the container, we attach the bottom, which is usually made of fibre but can also be made of metal.

Finalisation and quality control

Once the body of the container is finished, a visual inspection is carried out both internally and externally, and if everything is correct, the only thing left to do is to add the lid (plastic or metal) and the spring-loaded closure.

Each drum is subjected to strict quality controls to ensure that it meets the required standards of strength, tightness and safety.

More than just packaging

The manufacture of Kraft drums is a process that combines craftsmanship and innovation, ensuring that each container not only fulfils its practical function, but also contributes to environmental sustainability.

Frequently Asked Questions (FAQs)

What safety measures are implemented during the manufacturing process of Kraft drums?

During the manufacturing process of Kraft drums, various safety measures are implemented to protect both the workers and the product. These include the use of personal protective equipment, constant supervision of operators and proper maintenance of machines to prevent accidents and ensure a safe working environment.

How long does it take to manufacture a Kraft drum from start to finished product?

The time required to manufacture a Kraft drum can vary depending on the size and complexity of the drum, as well as other factors such as factory capacity and product demand. In general, it can take from several hours to several days to complete the manufacturing process of a Kraft drum.

What measures are taken to ensure sustainability in the manufacture of Kraft drums?

Several measures are taken to ensure sustainability in the manufacture of Kraft drums. These include the use of recycled materials in the production of Kraft paper, the optimisation of production processes to reduce the consumption of energy and natural resources, and the minimisation of waste through the implementation of recycling and reuse practices.

Can Kraft drums be customised according to the customer’s needs?

Yes, Kraft drums can be customised to customer requirements in terms of size, design and load capacity. This allows customers to tailor the drums to their specific storage and transport requirements, increasing their versatility and utility in a variety of industrial and commercial applications.

What quality guarantees come with the Kraft drums manufactured?

Manufactured Kraft drums typically come with quality guarantees and certifications that ensure their conformity to industry standards and their suitability for their intended use. These guarantees provide customers with the peace of mind that they are purchasing a high quality product that has been tested and certified by competent authorities.