Life Cycle Assessment (LCA): the Key to Choosing Sustainable Industrial Packaging

When discussing sustainability in the industry, packaging is often one of the first areas of focus. How can we tell if a container is truly more environmentally friendly or if it just appears to be?

This is where Life Cycle Assessment (LCA) comes in, a tool that allows us to objectively evaluate the environmental impact of a product from its origin to its end of life.

A method that measures everything, from the cradle to the grave

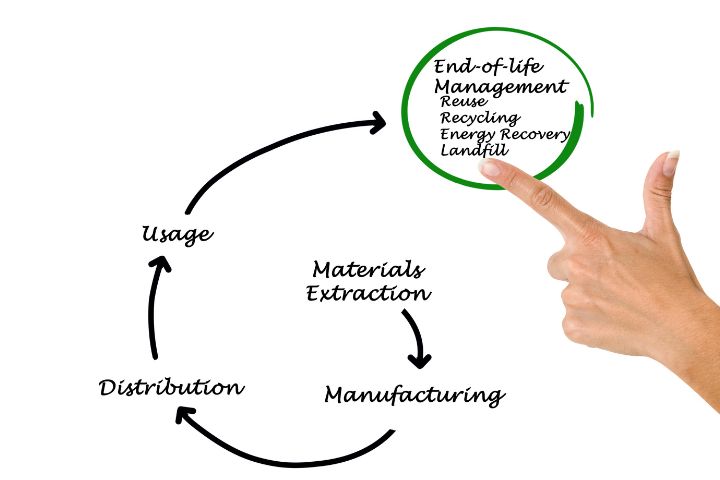

ELCA is a methodology regulated by ISO 14040 and 14044 standards. Its objective is to analyse the environmental impacts of a product or service at all stages: raw material extraction, manufacturing, transport, use and end-of-life management.

This comprehensive approach, known as “cradle to grave“, provides a clear view of the true environmental costs of each decision in the value chain.

Why is it key for industrial packaging?

Packaging is not just a matter of aesthetics or logistics. It accounts for a significant percentage of the environmental impact of many industrial products, especially in sectors such as pharmaceuticals, chemicals and agri-food.

With a well-designed LCA, different materials and formats can be compared not only in terms of their recyclability, but also considering broader aspects such as the emissions generated during their manufacture, transport efficiency and end-of-life behaviour.

That is why it is so important to ask the following questions when starting any packaging change project:

Which options have the smallest footprint?

What is the real impact of this change?

Which alternative best meets environmental criteria without compromising safety?

How ACV benefits your company

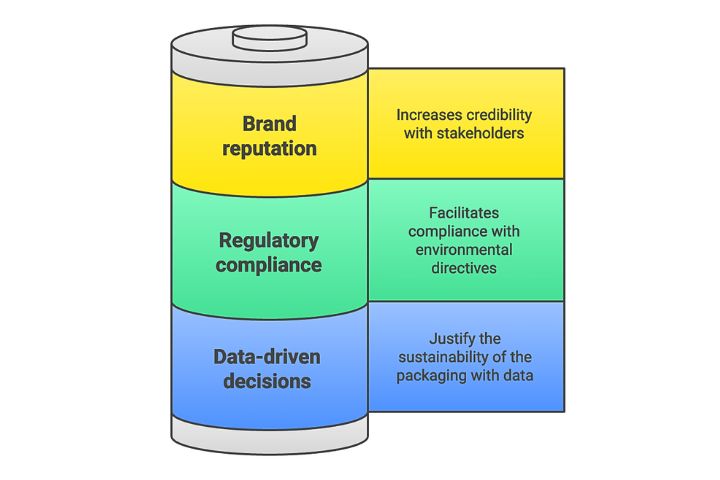

The first major benefit of LCA is that it helps make decisions to be made based on data, not perceptions. In a context where green marketing messages abound, having a comprehensive life cycle analysis allows for technical justification of why one packaging option is more sustainable than another.

Furthermore, many European regulations and voluntary standards are beginning to require this type of assessment. Integrating LCA into your packaging strategy facilitates compliance with environmental directives and certifications that require transparency and traceability.

Added to this is reputational value. Brands that incorporate these types of tools into their operations gain credibility with increasingly demanding customers, distributors, and consumers.

Materials such as kraft paper are in a favourable position.

Although the LCA result depends on the specific use and context, some materials stand out for their good environmental performance at different stages of the cycle. This is the case with kraft paper, especially when it comes from renewable sources and is used in lightweight, reusable designs.

Compared to other materials that are more complex or difficult to recycle, kraft paper generally requires less energy to produce and facilitates reverse logistics, making it ideal for return systems or circular economy models.

Applying ACV to real decisions

You don’t have to be a large multinational to integrate LCA into your packaging decisions. In fact, many SMEs are using this approach to redesign packaging, select new suppliers, or even prepare more robust sales pitches.

The important thing is to incorporate the life cycle perspective from the outset. Not just at the end, when a design has already been chosen. Including this analysis in the design or purchasing phase can avoid unnecessary costs, reduce environmental impact, and align packaging with company values.

Responsible packaging: beyond recyclability

It is common to associate sustainability with recycling, but LCA reminds us that what is sustainable is not always recyclable, and vice versa. Recyclable packaging can have a very high impact in terms of its manufacture or transport. And non-recyclable packaging can be reused many times, generating less waste overall.

That is why we insist that it is essential to question and analyse each decision comprehensively. In sectors where product safety is critical, having approved solutions that also perform well environmentally is a competitive advantage.

What role do we play?

For decades, we have been developing packaging solutions focused on offering both technical performance and environmental value. Our kraft fibre drums have been optimised to be recyclable, reusable and manufactured according to energy efficiency criteria.

We collaborate with companies that are looking for more than just a supplier: they are looking for a partner who understands regulatory requirements, the pressure to reduce their footprint and the need to convey these values to their customers.

Are you interested in applying LCA to your packaging?

If you are rethinking your packaging strategy or want to know if your current packaging is truly sustainable, we can help you analyse the alternatives and make decisions based on technical and regulatory considerations.

It’s not just about complying with mandatory requirements. It’s about staying ahead of market demands and demonstrating a real commitment to industrial sustainability.

You may also be interested in: